Conveyor Chain Vs Drive Chain

- Share

- Issue Time

- Jun 19,2021

Summary

Conveyor chains and drive chains are very different in features and functions, but many people tend to confuse them.

Conveyor chains and drive chains are widely used chains, but their characteristics are very different from actual uses. When we use them, we need to make a clear distinction. The following is the difference between a conveyor chain and a drive chain.

The main function of the conveyor chain is to realize the conveyance of items, so compared with the drive chain, the most obvious difference is that the chain speed is slow, but the carrying capacity is large.

The most representative of the drive chain is the short-pitch precision roller chain. Its characteristic is that the pitch is increased to an integer, and there are many different pitch forms, which can unavoidably be blocked by debris and so on. After being familiar with the characteristics of the short-pitch precision roller chain, its application is very obvious.

The structure of the drive chain is composed of inner chain links and outer chain links. It is composed of five small parts: inner chain plate, outer chain plate, pin, sleeve, and roller. The quality of the chain depends on the pin and sleeve.

There are fewer types of drive chains, such as roller chains and toothed chains, which are mainly used for drive. Compared with the conveyor chain, the pitch is smaller and the length is shorter.

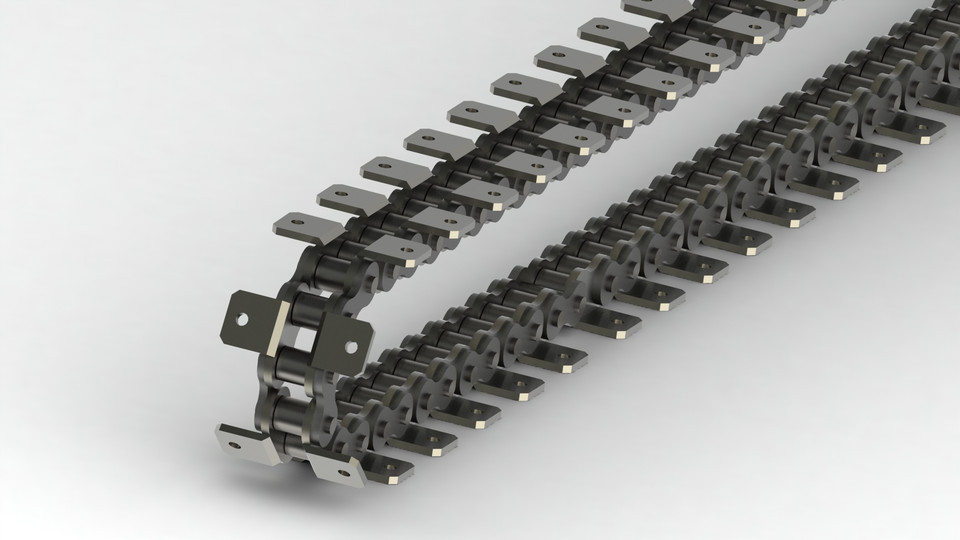

There are many types of conveyor chains, which are used for the transportation of various materials or articles, such as roller chains, round link chains, straight chains, curved plate chains, double-pitch chains, buried scraper chains, hoist chains, and so on.

Conveyor chain is also suitable for conveying various kinds of boxes, bags, pallets, etc. Some bulk materials, small items, or irregular items need to be transported on pallets or in turnover boxes. It can transport a single piece of material with a large weight, or withstand a large impact load.

In order to meet some special transportation requirements, the weight of the conveyor chain must not exceed the specified range, and at the same time, it must form a certain proportional relationship with the load it bears. At the same time, the wear resistance must also be small, because the conveyor chain has a small number of sprocket teeth and a large turning angle between the relative links when the conveyor chain is running, so it is easy to be worn. In addition, the conveyor chain must have specific impact resistance, high-temperature resistance, reliability, etc., to meet the requirements of use under special working conditions. However, the rolling resistance cannot be high, which is the basic condition for improving the efficiency and service life of the conveyor chain.

All in all, the main function of the conveyor chain is to convey materials, while the drive chain is mainly used to transmit power, which is different in use. If you want to know more about the conveyor chain after reviewing the above content, you can contact us for a detailed solution.

As a professional quality chain manufacturer, we always insist on providing customers with quality products and services. Professional production technology and experienced staff have won unanimous praise from many customers. We can also provide customers with thoughtful one-stop service and effective solutions. If you are interested in our conveyor chain, please contact us immediately!