What is a Conveyor Roller Chain?

- Share

- Issue Time

- Jan 7,2022

Summary

This article will give you a detailed introduction to the structure and characteristics of the conveyor roller chain to help you better apply the conveyor roller chain products.

Conveyor roller chains are usually used to power conveyors. Just like a bicycle chain, the conveyor roller chain provides more power to the conveyor belt. The conveyor needs a chain drive instead of a belt drive to avoid potential slippage.

The advantage of the conveyor roller chain lies in its ability to power mechanical devices without slipping or restraining under load. Conveyor drive systems usually use shear keys to avoid damage to the drive system or the conveyor if the conveyor is jammed. ZMIE summarizes the structure and characteristics of some conveyor roller chains.

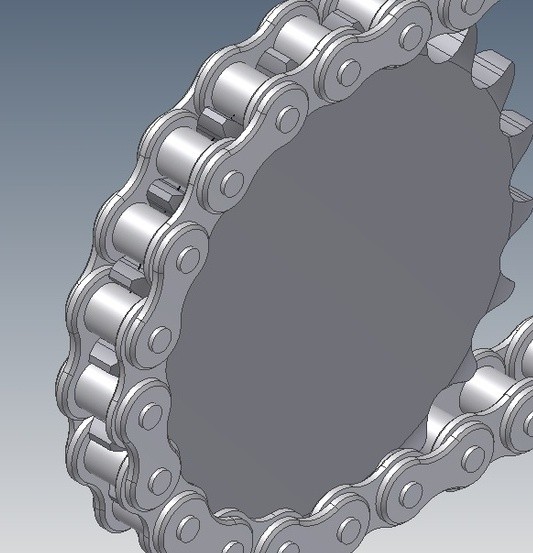

Roller chains are used in most sprocket applications that require strength and long life. The roller design allows the chain to roll off the sprocket teeth without causing the inherent wear of simple chain links and can be provided by reducing friction Long life and the ability of the chain to maintain lubrication.

Some of the best types of conveyor roller chains also include small rubber O-rings in each link to increase the lubricity of the chain. The number of the roller chain adopts numbers, and a sprocket set of matching sizes must be used to avoid damage to the chain and sprocket.

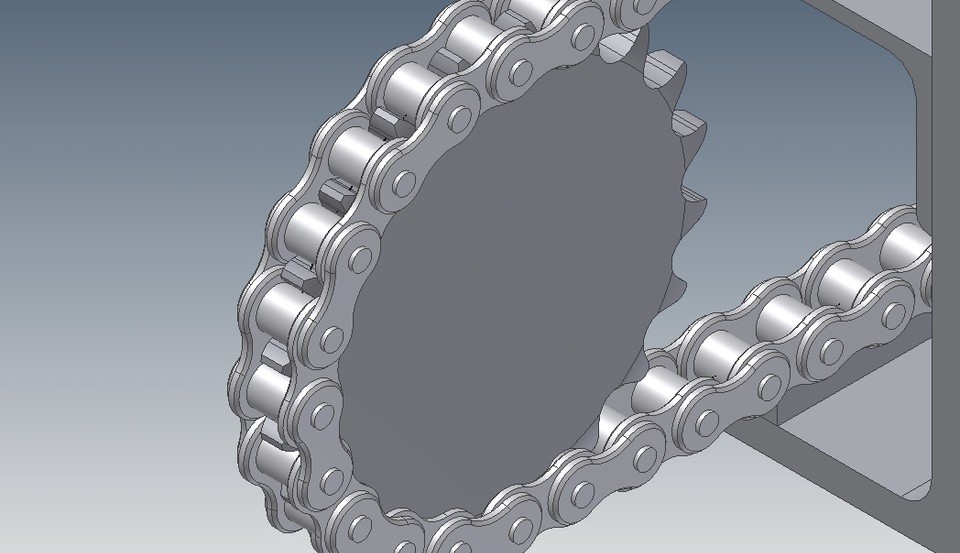

Conveyor roller chains can power the conveyor in one of two ways: power a driveshaft or roller, or connect directly to the conveyor. The most common method involves turning a rubber or canvas conveyor belt with a conveyor roller chain that powers the drive shaft.

In this application, the conveyor stretches between two or more shafts with rollers or sliding support between them. One end of the sprocket of the axle is connected to a sprocket, which leads to a drive motor that is usually driven by electric or hydraulic pressure.

For some conveyor designs, the roller chain is directly connected to the conveyor through the use of small steel brackets. The chain passes over the drive sprocket, which provides power to keep the conveyor moving. This design is used for heavy conveyors, which are used to carry extremely heavy weights over long distances, and conveyor systems used in humid environments.

Conveyor roller chains require regular maintenance, which usually includes cleaning, tightening, and oiling. If the chain is too long or too short, you can adjust the length by removing or adding links until the desired length is reached.

When we choose the conveyor roller chain, we need to match the conveyor model to choose the appropriate specification roller chain. ZMIE can provide diversified choices according to the needs of users. You can learn about it by reading the relevant content of our website.

As an experienced quality chain supplier, ZMIE has become a leader in the industry with its excellent manufacturing technology and considerate service, and many customers choose ZMIE for this reason. We are equipped with a professional production team and a strict quality inspection system to fully control the quality of our products. In addition, we can also provide a thoughtful one-stop service according to the needs of users. If you want to buy our roller chain, please contact us immediately!